Smart Vision Inspection Systems

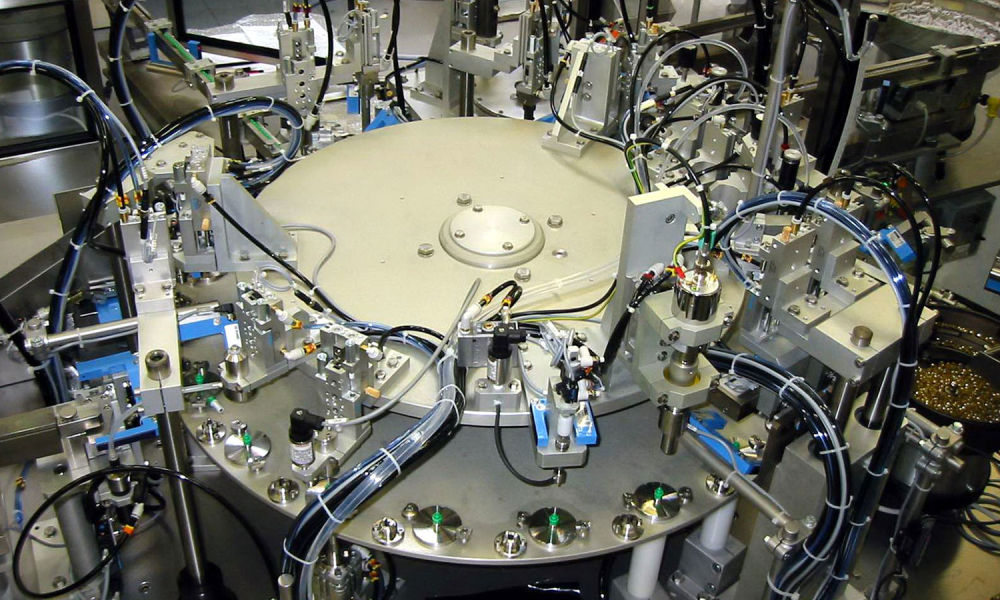

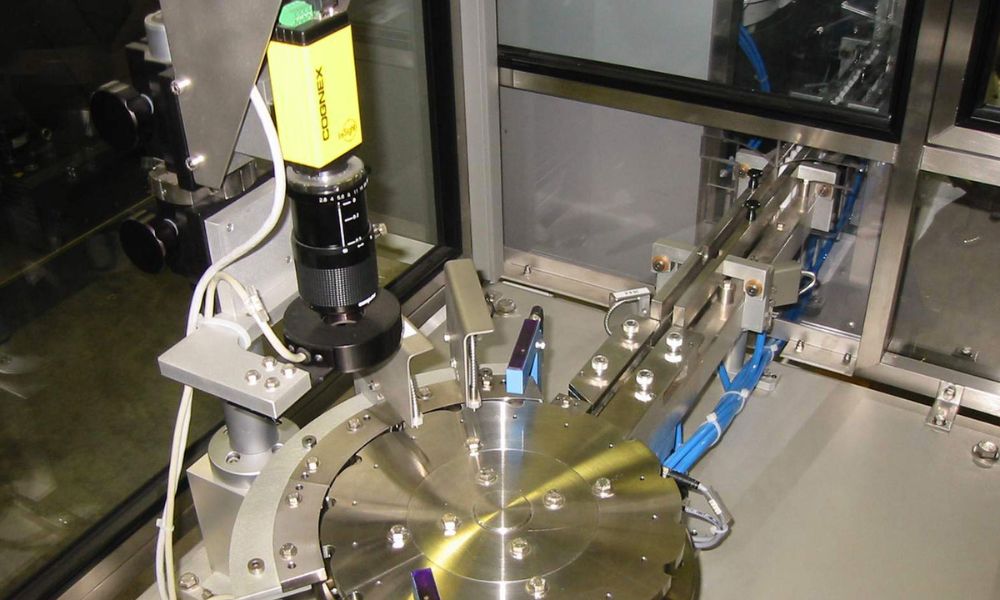

Logicontrol's Smart Vision Inspection Systems are advanced quality control solutions designed to detect defects, verify product integrity, and ensure compliance with stringent industry standards. Powered by AI-driven vision technology, these systems provide unmatched precision, speed, and repeatability in identifying flaws that are often invisible to the human eye.

Our inspection solutions integrate seamlessly with production lines, making them suitable for high-speed manufacturing environments. Whether in automotive, electronics, pharmaceuticals, or consumer goods, Smart Vision Inspection Systems help businesses minimize waste, improve product quality, and enhance customer satisfaction.

Key Features

-

AI-powered defect detection with high accuracy

-

Real-time inspection and data logging

-

Integration with PLCs, robotics, and conveyors

-

Capable of surface, dimensional, and assembly verification

-

Customizable algorithms to suit specific industry needs

Applications

-

Automotive component inspection (fasteners, wiring harnesses, engine parts)

-

Electronics inspection (PCB soldering, connectors, and microchips)

-

Pharmaceutical packaging and labeling verification

-

Food and beverage defect detection and quality grading</p|>

-

Consumer goods assembly and finish quality assurance

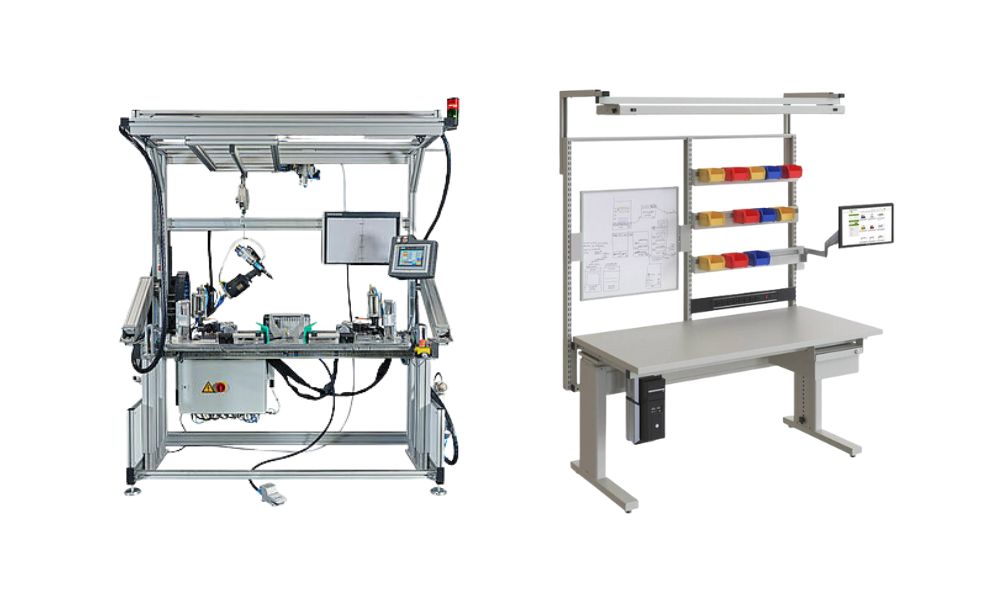

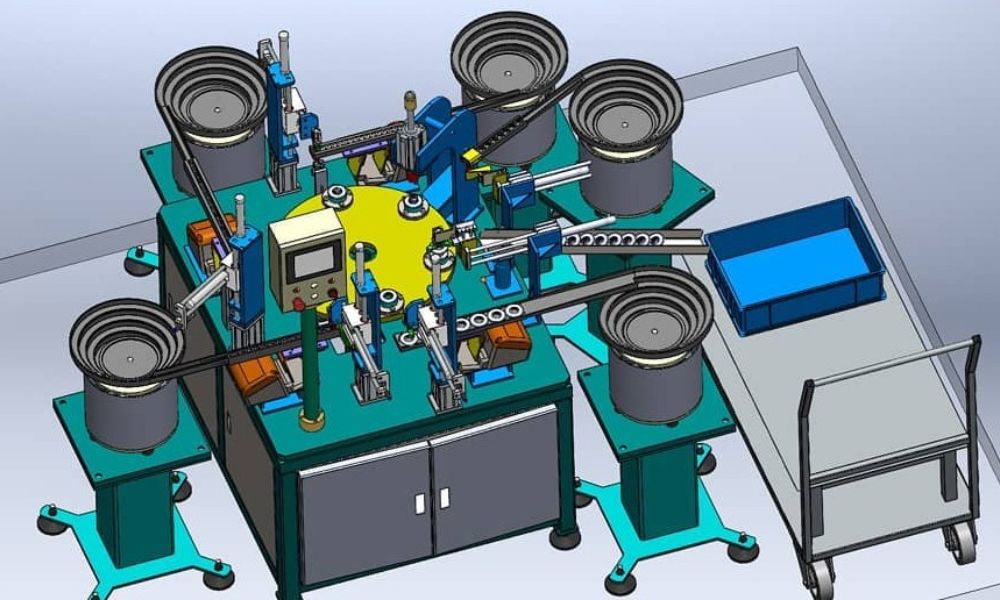

Our Specialized Vision Inspection Machines

-

2D Vision Inspection System – High-speed system for surface defect detection, label verification, and dimensional checks.

-

3D Vision Inspection Machine – Captures depth, shape, and surface variations for complex part geometries requiring advanced analysis.

-

Inline Vision Inspection Station – Integrated directly into production lines for real-time defect detection and rejection.

-

AI-Based Adaptive Vision System – Learns and adapts to varying product features, ideal for industries with frequent design changes.

Benefits

-

100% inspection with high accuracy and repeatability

-

Reduced rework, scrap, and production downtime

-

Improved compliance with industry quality standards

-

Enhanced production efficiency with real-time feedback

-

Scalable systems adaptable to future product changes