Machine Data Monitoring

Logicontrol's offers advanced Machine Data Monitoring (MDM) solutions that provide real-time visibility into machine performance, productivity, and utilization. By leveraging Industry 4.0 technologies such as IoT, cloud computing, and analytics, our MDM systems enable manufacturers to track key parameters, minimize downtime, and improve overall equipment effectiveness (OEE).

The system collects data directly from CNC, VMC, presses, and other critical machines, converting it into actionable insights for decision-makers. With continuous monitoring, industries can detect anomalies, optimize production schedules, and enhance efficiency while reducing operational costs.

Key Features

-

Real-time tracking of machine status, utilization, and performance metrics.

-

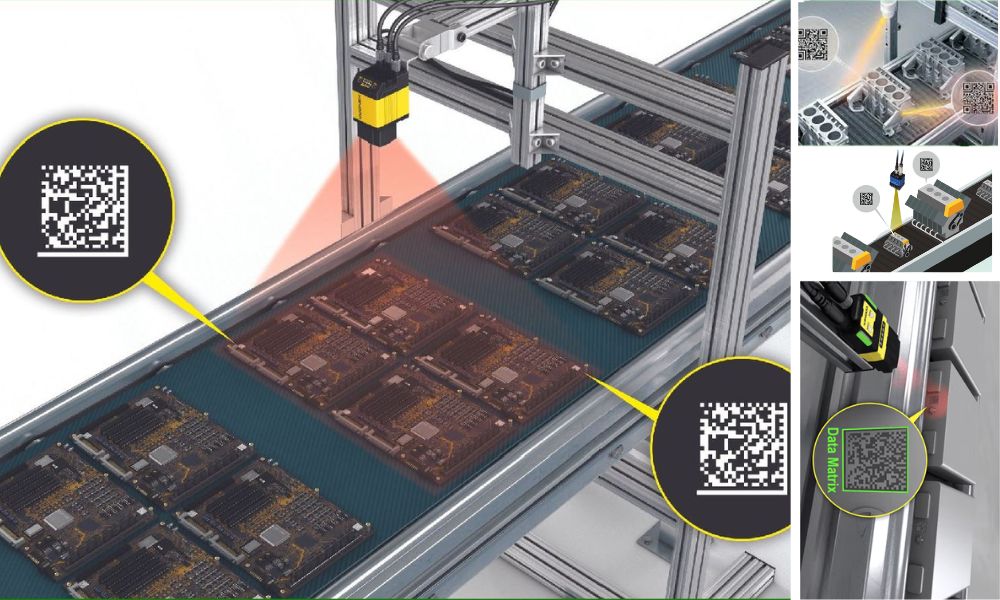

Automated data collection from CNC, PLC, and IoT-enabled machines.

-

OEE (Overall Equipment Effectiveness) reporting and analysis.

-

Alerts for downtime, idle time, and abnormal operations.

-

Centralized dashboard for monitoring multiple machines and plants.

Applications

-

Automobile and auto-component manufacturing units.

-

Heavy engineering industries with multiple CNC/VMC machines.

-

Process industries requiring continuous monitoring.

-

Electrical and electronics manufacturing setups.

-

Multi-location factories requiring centralized machine data visibility.

Benefits

-

Improves productivity by reducing machine downtime.

-

Enables data-driven decision-making with accurate machine insights.

-

Optimizes resource utilization and workforce efficiency.

-

Supports predictive maintenance and reduces unexpected breakdowns.

-

Increases profitability through higher OEE and better planning.

Logicontrol's – Driving smart manufacturing with Machine Data Monitoring solutions that empower industries to achieve maximum efficiency, reliability, and competitiveness.